Historically, energy analysis has always been time consuming. It required one to undertake hours of data collection over the period of a day, week or even a year. Once data was collected, one could then convert all consumption data into useable standard units i.e. kWh.

At this point, data analysis could take place which would involve the production of percentage breakdowns of total consumption and cost. This would allow the user to gain an understanding of where energy use and (more importantly) potential energy waste might occur. This process however, took a significant amount of time to compile and could not conduct with highly granular energy data. These are no longer issues however, thanks to our new analytical tool.

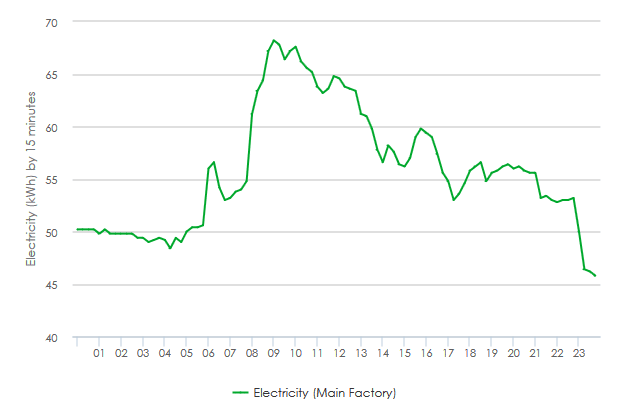

Our data analysis tool Advisor, strips the unnecessary steps from energy analysis and allows users to quickly and easily understand where energy is being used. Advisor takes a snapshot of data usage every 15 minutes and displays it in an easy to read, graphical way. Let’s take a look at what 24 hours of data can show us.

The graph shown below in Figure 1 is 24 hours of data recorded from a site concerned with the production of plastic products. Querying site knowledge, we have found that the working hours for this site are 8am to 10pm and that there are multiple “heavy” loads on site. The largest of these are 2 ovens, 3 industrial grade compressors and a HVAC system.

The graph displays data from the sites Main Electrical Incomer datasource. By looking at the data, we can see that production ramps up from 8 am and slowly decreases throughout the day until late at night. Plant shutdown should be at 10pm and prior to this time, there should be a ramp down period as manufacturing slows to a stop for the night. However, we see immediately that this is not the case. It is admitted that this is a daily occurrence for the company and it is deemed to be an unnecessary behaviour. This poor shutdown policy is costing them approximately €75 a day, which if we run this figure over the course of a year we can see the company can save upwards of €18,000/year with a single change in behaviour.