This investigation was conducted on the Main Incomer for the site, which meant that the reactive (inductive) load could be separately monitored. The reactive loads are important because they cause the current to become out of phase with the voltage.

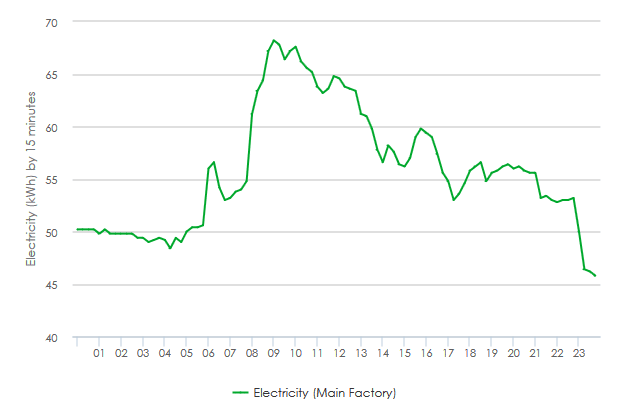

It is the consumer who will pay for the additional current required for inductive electrical loads. Over the course of this single day, we revealed that the sites Power Factor was excellent for the vast majority of the time but dramatically deteriorated as the day drew to a close. Onsite investigation revealed a change in operation from 6pm onwards. This change came in the form of a varied load, unlike the consistently high load of the peak manufacturing time of 8am to 6pm. The supply voltage is increased during this period which in turn increases the magnetising current and causes a decrease in power factor. Several induction motors are used at the low end of their capacity during the 6pm to 10pm time range, for a secondary stage of manufacturing. At decreased load, these motors were exhibiting a very poor power factor of 0.3. This knowledge allowed us to quickly compound our power factor investigation and recommend an upgrade to the appropriate size of motor equipment.

Although this site has power factor correction equipment, it is important to ensure that it is set up for the sites attributes and that it is functioning correctly. Power factor elements or Wattless loads are a billable unit once you surpass the agreed threshold of 1/3 of the kWh load for the site. This is usually seen on your bill as “low power factor surcharge”.

The graph shows us that from 5pm onwards, there is a rejuvenated effort in terms of energy consumption as it begins to rise once more. Querying the company, we were informed that a second shift of the day begins wherein a specialised workforce quality tests new products. This is conducted in a separate area otherwise unoccupied during the day. What the graph shows is the extra lighting being used due to the increase in hours of darkness experienced. However, through multi-variable analysis, we determined natural day light would be adequate for this level of testing and therefore recommended this specialised team be brought in earlier in the day. The testing could then be conducted on day old products rather than freshly produced products and the extra energy on lighting could be saved. This recommendation was only made after the specialised workforce assured us that testing a day later would not make any difference to the quality assurance for the product and is just another small change that could save the company upwards of €10,000/yr.

Overall, this brief insight into what can be achieved with 24hours of energy data enabled us to ask key questions and quickly dive into energy consumption and behaviours found on site. Once questions were derived, simple answers were returned from onsite knowledge and together formed a comprehensive list of energy saving opportunities.