The first step in good energy management practice for motive drives is to carry out an organisational survey of your motor assets. This survey can then be used to develop a motor register identifying as many parameters regarding the motor/drive and process as possible including details like, drive type e.g. V-Belt, etc. This data can easily be built into any spreadsheet application.

Once you have completed your motor register it can now be used for two primary purposes:

1) To develop a motor purchasing policy around future motor procurement within your organisation, and

2) To identify the motors that should be flagged for replacement in any capital works projects (while also be cognoscente of process operations and maintenance).

There are many areas where motive drives can affected overall energy efficiency within your organisation:

1. Power Quality – Poor power quality on site will have adverse effect on motor operations, increasing slip and motor inefficiency. (Power quality on site can be monitored with the use of a suitable power analyser to determine if this is the case).

2. Speed – Does you motor/process need to operate at 100% and all of the time, if not consider VSD as an option to control the process more efficiently.

3. Motor Selection – Select the right motor for the process conditions, many motors are generally oversized for the load requirements, this often happen as a causality of design with each engineer in the design adding a margin of error to calculations. When upgrading or replacing motors consider the process conditions and how the load might be better served if delivered by multiple reduced rating units. E.g. have 3no. 50% motor/pump combinations in place of the popular 2no. 100% duty/standby arrangements. This process setup will allow more agility within your system, provide the require redundancy (as you would be very unlikely to have two failures on one system simultaneously) and you have the added benefit of having 50% head space on your system.

4. Transmission – Consider your transmission system, ask yourself “Is this the best way to couple my load to my drive”, many transmission system as wasteful with you precious energy for example v-belts Vs. flat or ribbed belts, these generally improve transmission efficiency between 4-6%. If utilising a gearbox, consider its efficiency, why is it used, could this be upgraded or replace by a VSD, is it correctly aligned.

5. Process Loses – Can loses be prevented in the system itself?, for example can leaks be removed from pump system or bearings be improved on drives, and

6. Finally, the Process – Ask yourself is this process required? Is it carrying out useful work? Are we just pump fluid around in loops for no reason, can be shut down when not required.

So there is one final question in relation to motors I would like to address, ‘’Repair or Replace”.

It is commonplace for organisation to re-wind motors when they fail and indeed the motor maintenance policy may require that motor are re-wound say every 100,000 operating hours.

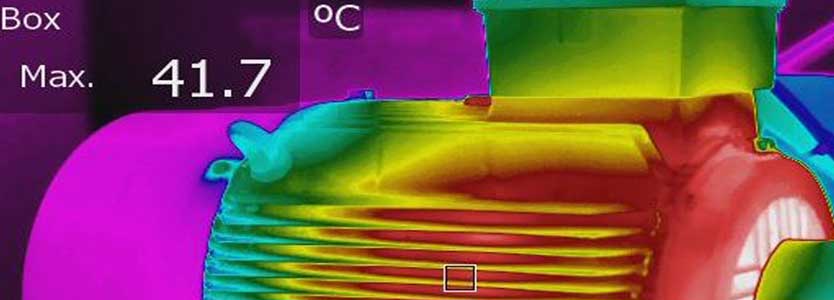

The decision to repair/rewind or replace will very much depend on the efficiency of the original motor Vs. the efficiency of available replacements on the market. In many cases this difference can be relatively small. Generally you can expect a re-wound motor to be 0.5-1% less efficient than a direct replacement and a new unit to be 2-4% more efficient than its predecessor. Remember a replacement is always an opportunity to re-size you motor to best fit you process requirements.

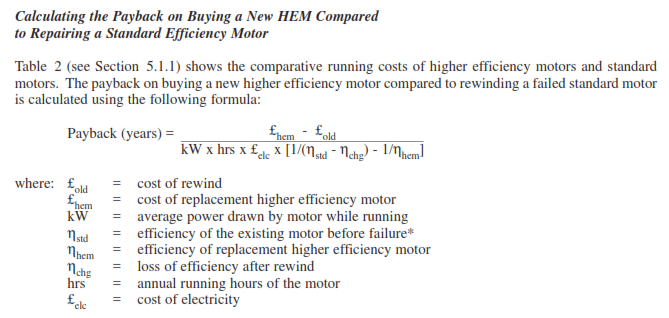

Here is a useful formula you can use to determine the best course of action (Source: UK department of the environment and transport, Good Practice Guide 2 “Energy Savings with Motors and Drives” 1998).